Generally, when someone needs to customize a clothing, a tech pack is often required to move forwards. So what is a tech pack, and why it necessarily?In this post, we’ll cover the fundamentals of creating a professional tech pack, breakdown the components and show you template to help create a tech pack easily.

What is a tech pack

Tech pack is short for technical package, and it’s an essential document in the garment manufacturing industry that contains all the details required to make a sample or bulk orders.

A well-prepared tech pack effectively communicates design intent, construction details, fabric specifications, and production timing, which simplifies the entire production process.

Through a tech pack, it’s easier for designer to capture all the vital information such as sizing, colors, and logo or graphic requirements, reducing the possibilities of miscommunication. This would save on production revisions and delays which means cost savings and on-time deliveries.

Who uses tech pack?

Tech packs are commonly used by fashion designers, product developers, and sourcing teams, as well as manufacturers who require precise specifications to create garments accurately

As a matter of fact, tech packs also playing an important role in maintaining quality control throughout the manufacturing process. Manufacturer would strictly producing the clothes base on the documented specifications and requirements. leads to higher quality garments that meet the expectations of consumers and maintain brand integrity.

Key Components of a Tech Pack

A well-structured tech pack is vital for effective communication between designers and manufacturers. The key components of a tech pack ensure that all necessary information for producing a garment is clearly stated, fostering accuracy and minimizing misunderstandings. Among these components are technical specifications, materials, measurements, construction details, and labeling.

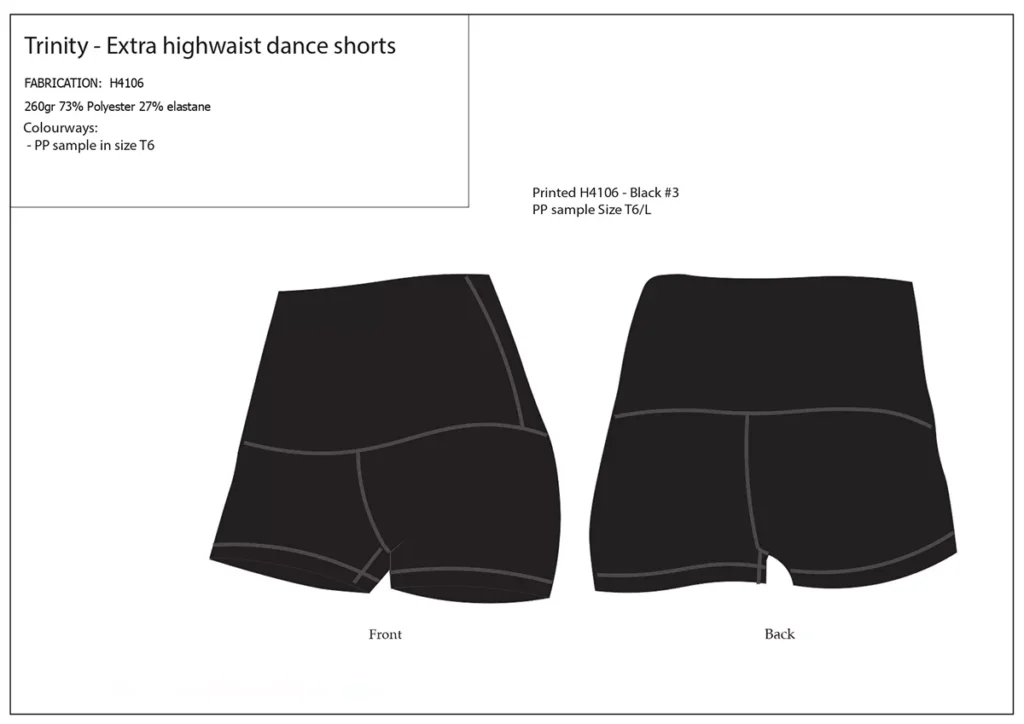

- Firstly, your garment design and features. Outline the sketches, color, and design, providing your manufacturers with a comprehensive view of the intended outcome, ensuring that everyone is on the same page to ensure the quality.

- Next, fabric information or requirements. Defining the exact materials helps to shorten fabric sourcing time and avoid mistakes, which can lead to costly production delays.

- Measurements for your garment. Here, precise dimensions for each size, grade rules for scaling, and fit specifications must be documented. This allows manufacturers to create patterns accurately and ensures the final garment meets the designer’s size requirements and fits the intended market.

In conclusion, each component plays a significant role in the overall effectiveness of a tech pack. By paying close attention to these elements, designers can facilitate a smoother production process and ultimately achieve a successful garment outcome.

Step-by-Step Guide to Creating a Tech Pack

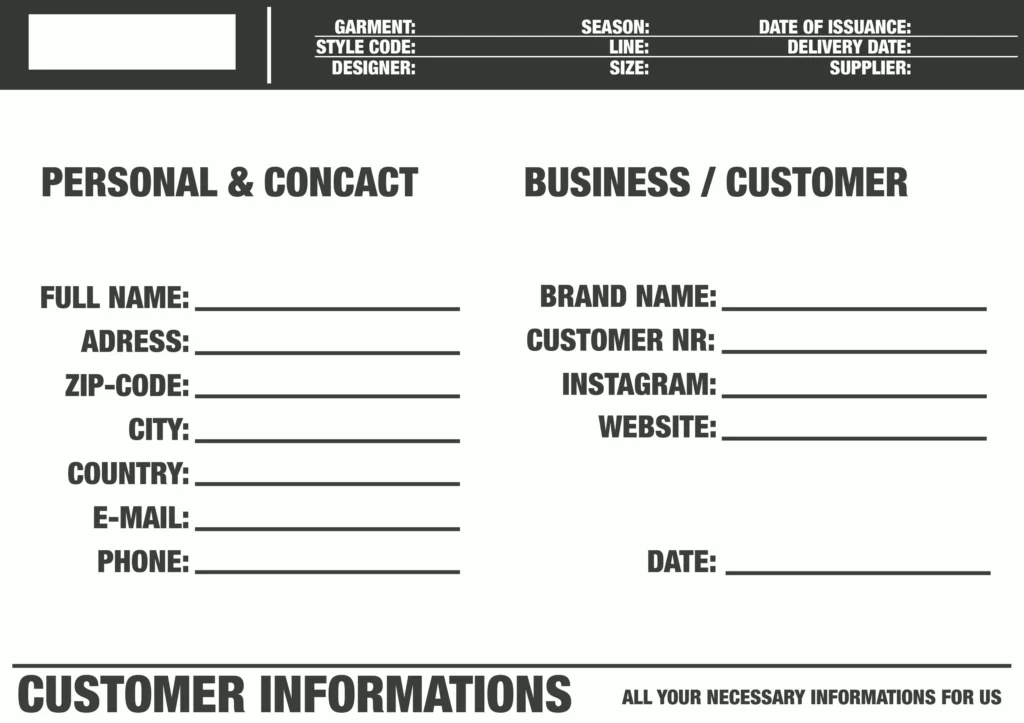

1. Garment Details & Basic Information

- Product Name & Style Number (Unique identifier for tracking)

- Season/Collection (E.g., Spring/Summer 2025)

- Brand/Client Name

- Target Market (Men’s, Women’s, Kids, etc.)

Show your purpose of this tech pack, help your manufacturer learn what this tech pack is about, and this will also help proper classification and archive filling.

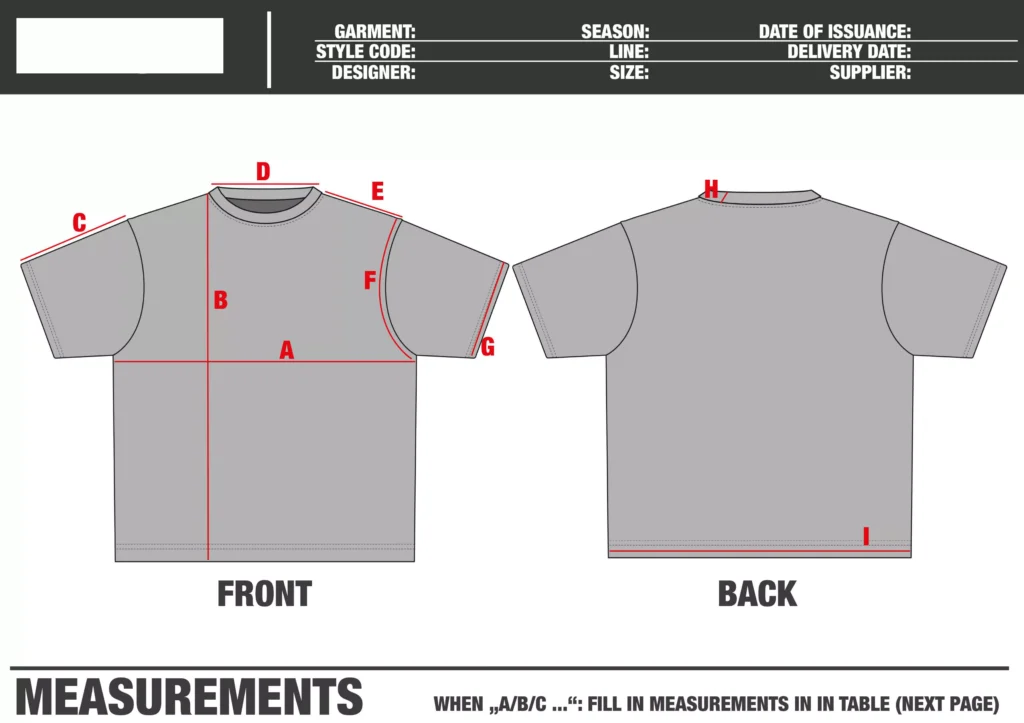

2. Technical Sketches (Flat Drawings)

- Front, Back & Side Views – Clearly labeled with stitching details.

- Close-up Views – For pockets, zippers, pleats, etc

- Digital or Hand-drawn (Use Adobe Illustrator or specialized fashion design software)

These sketches should represent your garment from multiple angles, highlighting essential features and construction details, this would assist manufacturers in understanding your vision easily.

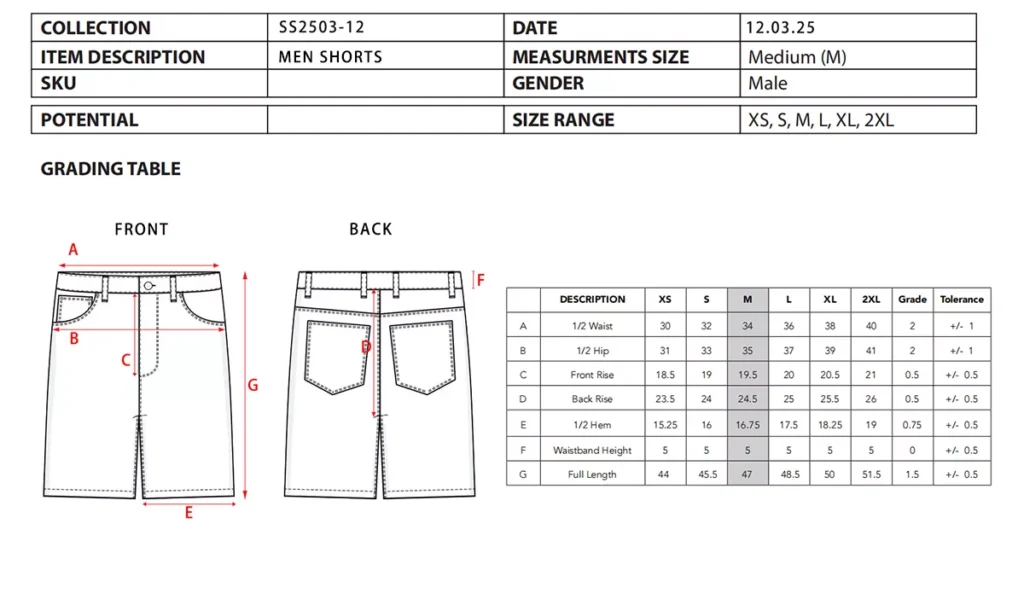

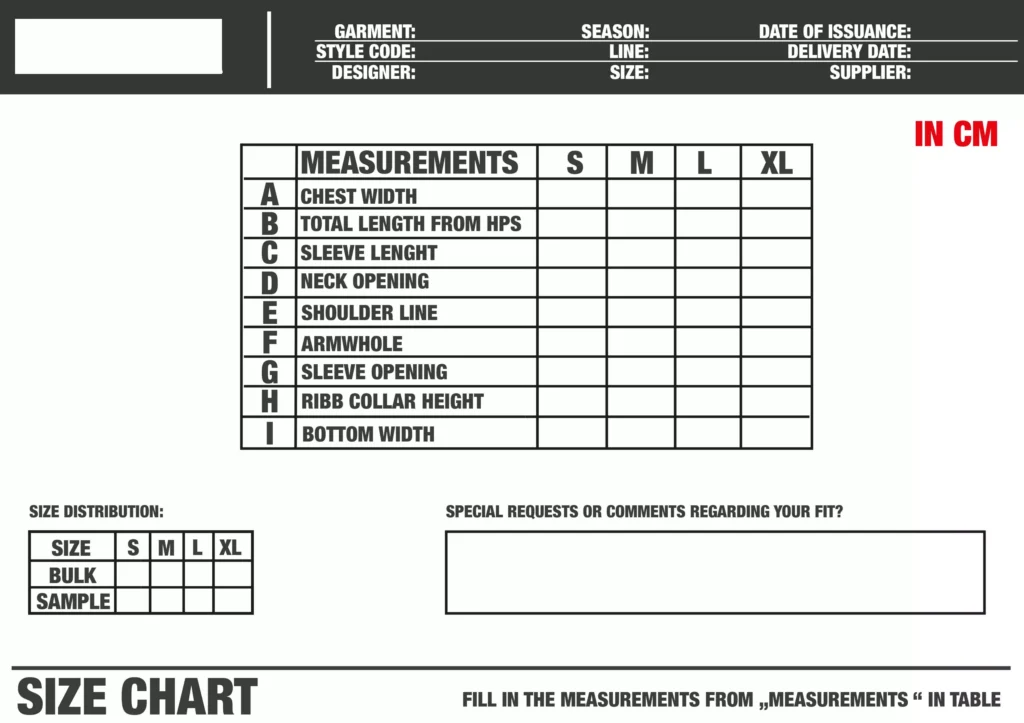

3. Measurements & Size Specifications

- Size Chart (XS to XXL or custom measurements)

- Tolerances – Allowable deviations (e.g., ±0.5 cm)

- Measure guidance-How the pattern adjusts for different sizes.

This involves establishing the measurements and proportions that correspond with your target market.

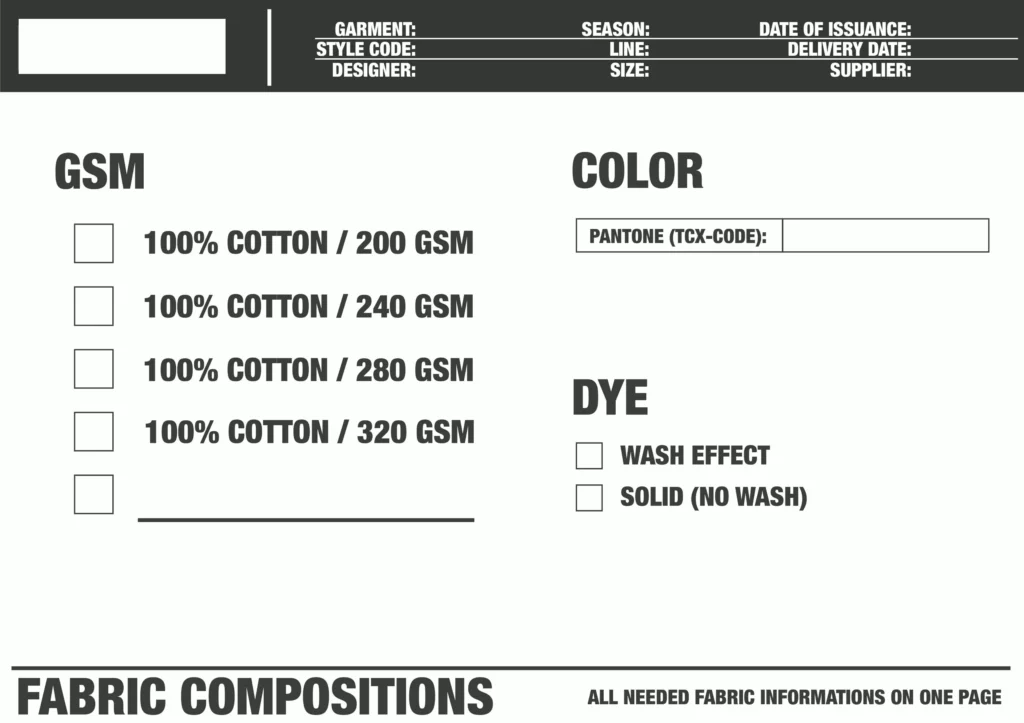

4. Materials & Trims

- Fabric Details (Composition, weight, GSM, supplier info)

- Thread Type & Color

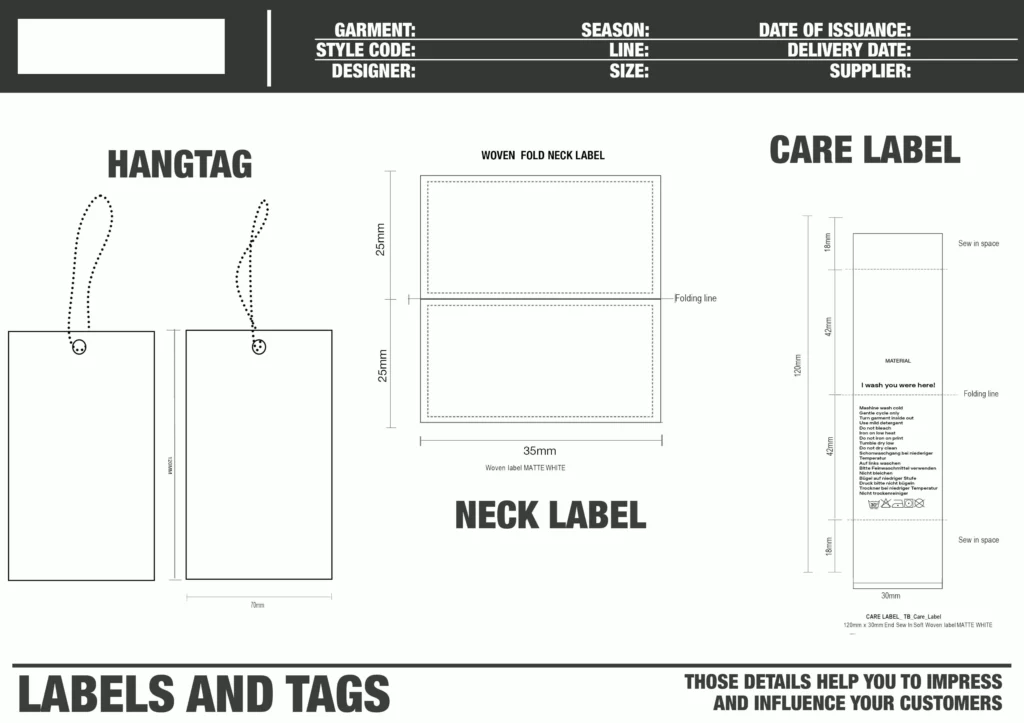

- Labels & Tags (Care labels, brand labels, hangtags)

- Zippers, Buttons, Elastic, etc. (Specify size, color, material)

Fabrics play a pivotal role in determining the overall quality and usability of the final product, breakdown the trims or accessories to avoid mistaken.

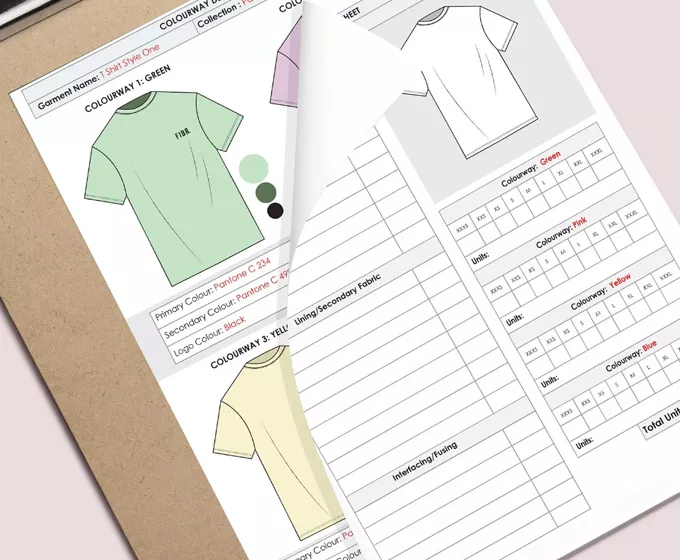

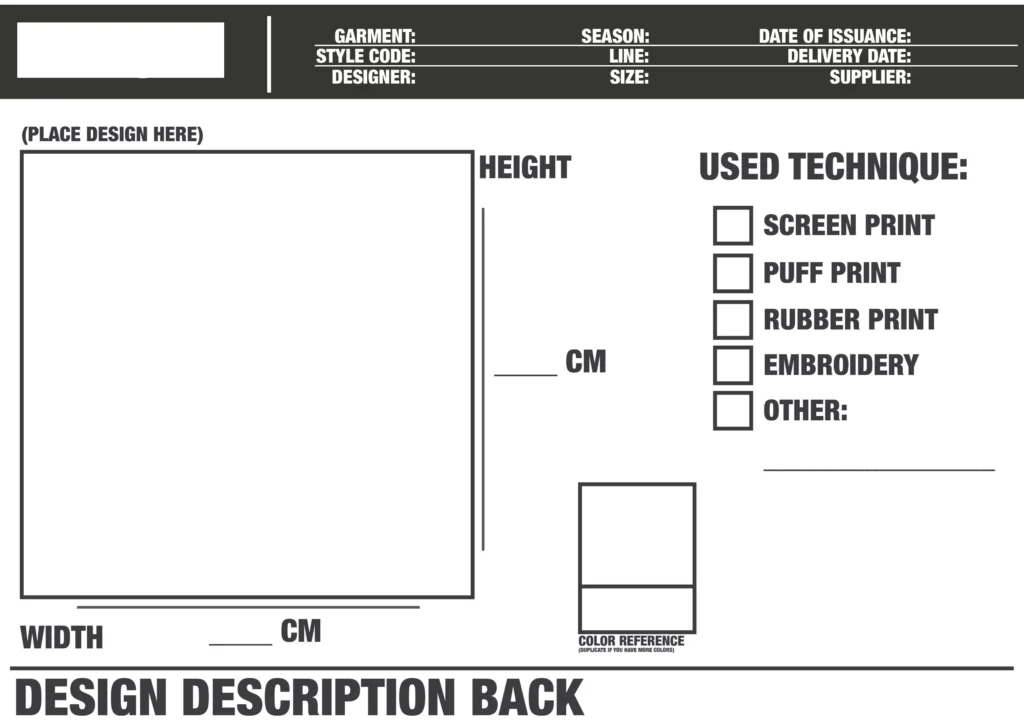

5. Colorways & Print/Embellishment Details

- Pantone Codes (Exact color references)

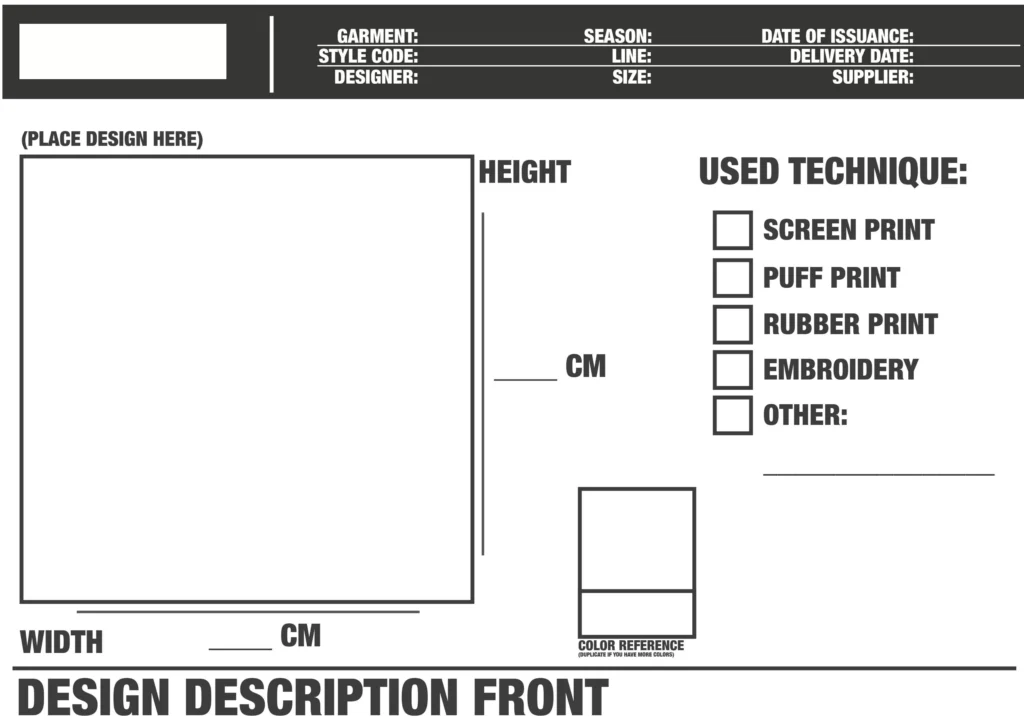

- Print Placement & Scale (For patterns or graphics)

- Embroidery/Appliqué Details (Stitch type, thread count, positioning)

Colors can appear different under natural light and artificial lighting. Pantone code would help improve this issue. Figure out the printing or embroidery details also help improving the final garment quality.

6. Stitching & Construction Notes

- Seam Types (Flatlock, overlock, French seam)

- Stitch Per Inch (SPI)

- Reinforcements (Bar tacks, bartacks at stress points)

7. Packaging & Labeling Instructions

- Folding Method (How the garment should be packed)

- Polybag Size & Labeling (Barcode, SKU, QR codes)

- Hangtags & Packaging Design

Filling all these information above into your excel or pdf file to finalize a tech pack, and then sharing it with your manufacturer. In most of the time, there would have some issues between manufacturing and your construction, not everything could be 100% made as your expected. This would need a deeper communication with your partner and manufacturer to get a better solution in order to get the best quality products.

Tech pack template for reference:

* Contact us free to get more blank template.